1.Principle of operation

Shielding pump

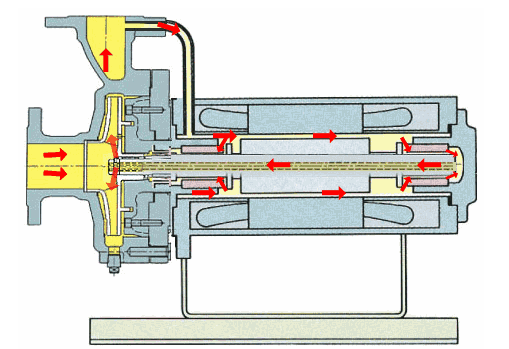

The principle of the canned motor pump is to isolate the stator and rotor inside the motor, and the outer ring of the stator and rotor is wrapped in stainless steel.Both the rotor and the pump impeller are on one shaft, and the rotor rotates with the impeller.The stator of the motor is wound around the stainless steel sleeve, and the rotor is also wrapped in stainless steel. The air between the stator and rotor of the motor itself is now turned into a conveying medium, but the medium is not in contact with the coil. This is the shielding pump.

Shielding pump structure

Magnetic pump

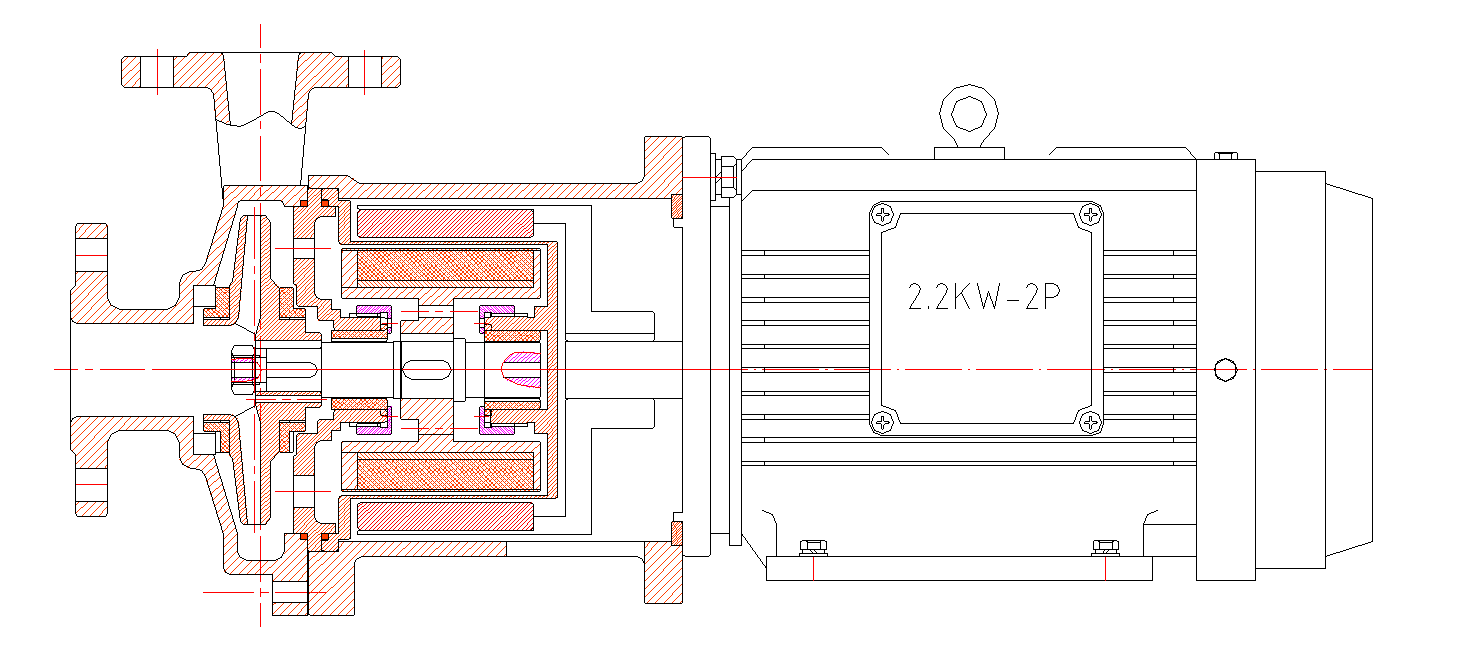

The whole machine is driven by an independent standard motor. The motor belongs to the national standard product and can be selected with any brand motor. Using the principle of magnet N-pole S-pole attraction, a special internal and external magnetism is designed. There is an isolation sleeve between the inner magnet and the outer magnet to isolate the conveying medium. The external magnetic field is driven by the motor, and the internal magnetic field rotates synchronously. Through a series of designs such as sliding bearings, pump shafts, and impellers, the pump transport medium is driven.

Magnetic pump structure

2.Advantages and Disadvantages

( 1 ) Sealing performance, bearing lubrication form

Shielding pump:The process medium part is fully sealed structure, and the bearing is lubricated by the process medium. Bearing box can not be installed, so no ball bearings.

Magnetic pump:The process medium is partially fully sealed, and the bearing is lubricated by the process medium. The ball bearings of some magnetic pumps with bearing boxes are lubricated with oil.

( 2 ) Safety performance

Shielding pump:Double-layer sealing of the shielding sleeve and the motor shell. Once the shielding sleeve is damaged, the motor shell also has a certain sealing effect, and the medium will not immediately leak into the air.

Magnetic pump:There is a layer of isolation sleeve between the medium and the air to play a sealing role. After the isolation sleeve is damaged, the process medium leaks into the bracket, and there is also a certain reaction repair time.

( 3 ) Pressure resistance

Shielding pump:The wall thickness of the can is generally 0.5mm. However, there is a stator as a support in the outer layer of the shielding sleeve, so the canned motor pump can withstand greater medium pressure.

Magnetic pump:The wall thickness of the magnetic pump isolation sleeve is generally between 0.75-1mm, and too thick wall thickness will cause magnetic eddy current. The outer layer of the isolation sleeve is in direct contact with air, so the limit pressure value is low.

( 4 ) Temperature resistance

Shielding pump:-50 °C - + 400 °C.

Magnetic pump:-100 °C - + 360 °C.

( 5 ) Viscosity range

Shielding pump : 0-100Cps, the heat generated by the motor of the canned pump will slightly reduce the viscosity of the medium.

Magnetic pump : 0-70Cps, the magnetic eddy current of the magnetic pump will also produce heat, but the heat is not as high as that generated by the shielding motor.

( 6 ) Noise

Shielding pump : low noise.

Magnetic pump : the noise is higher than the canned motor pump, because of the existence of the motor fan, and the existence of the motor ball bearing.

( 7 ) Couplings

Shielding pump : unable to choose.

Magnetic pump : optional.

( 8 ) Main failure points and maintenance workload

Shielding pump : two sliding bearings, two sleeves, canned motor, stator canned sleeve, rotor canned sleeve, impeller friction ring.

Magnetic pump : two sliding bearings, two bushings, impeller friction ring.

( 9 ) Whether to return to factory maintenance

Shielding pump : bearing and shaft sleeve can be repaired and replaced on site, but the two canned sleeves need to be returned to the factory for repair, and the stator and rotor need to be wound again if damaged.

Magnetic pump : All spare parts can be replaced on site without returning to the factory.

( 10 ) Shield thickness and isolation sleeve thickness

Shielding pump : 0.5-0.6mm

Magnetic pump : 0.75-1.2mm

( 11 ) Particle tolerance

Shielding pump : can 't transport medium containing particles, especially the high hardness of the particles will break the shielding sleeve

Magnetic pump : In principle, it can not transport particles, but due to the thickness of the isolation sleeve is thick, the impact of impurities scratching the isolation sleeve is smaller.

( 12 ) Efficiency

Shielding pump : The gap between the stator and the rotor is very large due to the over-current, so the larger inner rotor is needed to achieve the same power, so the disc friction loss is very large. Low efficiency.

Magnetic pump : According to the different energy efficiency of the matching motor, the unit efficiency of the whole machine can be improved or reduced. Because the magnetic pump is a coupling transmission of permanent magnets, the inner rotor is small, and the disc friction loss is small. The efficiency of the whole unit is about 10 % higher than that of the shielded pump.

( 13 ) Whole machine price

Shielding pump : complex process, relative to the magnetic pump price 30 % -40 % higher%

Magnetic pump : the structure and process is relatively simple, much lower than the shielding price.

( 14 ) Accessories Price

Shielding pump: the repair price is high, the price of stator and rotor rewinding is very high.

Magnetic pump : In addition to the high price of permanent magnets, the prices of other accessories are relatively low.

Shielding pump : return to factory maintenance time is not controllable, occasionally affect the field use.

Magnetic pump : the factory can repair itself, repair a magnetic pump time up to 1 hour.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318